FDM (fused deposition modeling) 3D printing is one of the most practical and popular 3D printing technologies today due to its ability to print a wide range of materials (i.e., polymers, composites, metals). One such material is PET, a polymer most notably used to make plastic bottles, among other consumer packaging products, making it one of the world’s most-used plastics. Due to its adaptability, PET has become popular as an FDM 3D printing material in the modified version called PETG.

PETG is a reliable and affordable material with a lot to offer for designers and engineers, among other users. Through this article, you will find more information about this versatile filament, including benefits, drawbacks and how to get the best results for PETG 3D printing.

PET AND PETG – VERSATILE POLYMERS

Chemical Composition

PET (polyethylene terephthalate) is a transparent and lightweight thermoplastic polymer resin part of the polyester family that is derived from petroleum. First synthesized by the DuPont Company in the 1940’s, PET has become the world’s most used plastic. PET can be easily modified for use in a wide range of applications with the modifier being identified as a suffix letter in the name.

PETG is a modified version of PET, with the “G” standing for “Glycol,” a molecule added during the polymerization process to make it less fragile, more durable and easier to use. This version is preferred for FDM filaments used in additive manufacturing and is generally translucent but also available in a range of colors. PETG exhibits excellent mechanical properties and also boasts resistance to moisture, chemicals and heat, particularly when compared to PLA.

Applications of PET

Food and beverage packaging often takes advantage of PET in the form of PETE due to its limited reactivity to moisture and chemicals. PETE is one of the most commonly recycled types of plastic due to its sheer volume of production.

Packaging for consumer products other than foods such as cosmetics, soaps and detergents, and various other reactive chemicals are used by major consumer products companies.

The textiles industry utilizes PET in both new and recycled form to create polyester fabrics. These textiles products can range greatly – from fleece jackets to sleeping bags to dog beds and much more.

In dentistry and orthodontics, PETG is used for dental aligners with some of the more recent brands, creating plastic, form molded alternatives to traditional metal braces

PETG 3D PRINTING

Applications of PETG 3D Printing

PETG is now widely available as a filament for FDM 3D printers and, thanks to its material properties, has become popular in a number of different professional applications.

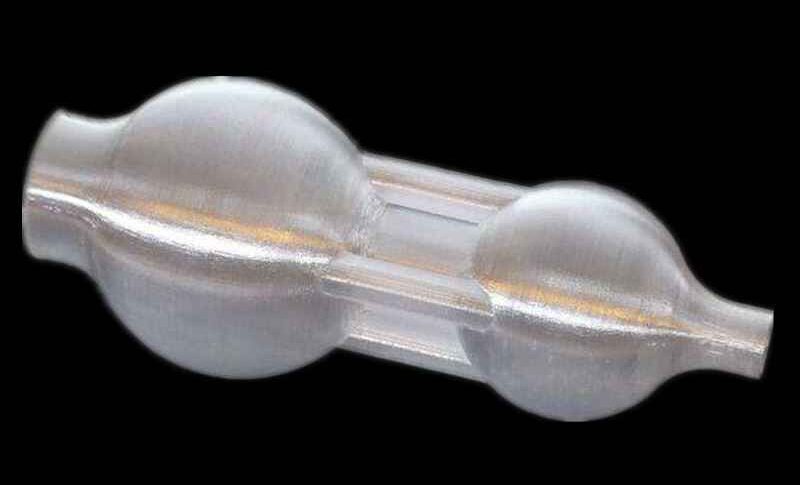

When working on new concepts, designers and engineers can take advantage of its transparency, moisture and chemical resistance to make great functional prototypes such as containers for liquids, signage and graphic displays, enclosures for electrical equipment, etc. The most obvious use of PETG 3D printing is for the design and prototyping of the packaging for consumer products that will be later made out of some form of PET when it enters mass production.

Also suited for more demanding environments, where heat and chemical resistance is required in addition to mechanical resistance, machinists and manufacturing engineers can use PETG to create durable custom parts such as manufacturing tools and aids, testing components or robotic end effectors.

Additionally, because PETG remains a durable and performant polymer, engineers and machinists can create true end-use parts including snap fits and living hinges, protective guards or custom machine parts.

Tips for PETG 3D Printing

The material properties for PETG vary depending on the material grade or producer, so it is best to follow the manufacturer’s recommendations first and foremost (MakerBot PETG, for example, is optimized and tested to work with METHOD and thus the default settings will yield optimal results).

Generally, PETG’s melting point is around 260°C, and it starts transitioning to a more liquid state at about 230°C. Don’t forget to ensure your FDM extruder and nozzle are able to heat up to temperatures in this range. Additionally for best results, it is recommended to use an FDM 3D printer with a heated print bed or, even better, a heated build chamber with a temperature setting somewhere around 60°C-80°C. This will enable better temperature control when the polymer starts to solidify and minimize the risk of warpage.

For optimal adhesion of the part in PETG 3D printing, it is highly recommended to use a build plate adhesive – a regular old glue stick will work for this. This will help prevent the print from curling off of the print bed which can be a common occurrence in PETG 3D printing.